Why Center Pivot Irrigation

The center pivot offers the perfect platform for sprinklers to deliver the right amount of water in the right way.

Nelson Irrigation has a full range of products from the pivot point to the end gun. Create the system that's right for your crops with control valves, pivot sprinklers, pressure regulators, and end guns, and the package is complete. Efficiency and effectiveness are at the heart of this superior center pivot irrigation package.

Table of Contents

- Why Center Pivot Irrigation

- Why Choose Nelson Center Pivot Products?

- Pivot Point to End Gun Solutions

- Efficient, Effective, Economic

- Sprinkler Technology: Modular 3030 Series w/ the 3NV Nozzle

- Testimonials

- Celebrating 50 Years

- World-Class Manufacturing

- Recommended Products

- Irrigation Education - Pivot Webinar Library

- Latest Blog Posts

- Resources

- GeoCropical® Solutions

- FAQ

- Glossary

Why Choose Nelson Center Pivot Products?

- Built in Walla Walla for Global Applications

- Innovative Sprinkler Technology for the Future

- Customizable Systems to Meet Unique Needs

- Flexible Configurations for Mount Up-Top & On-Drops

- Low-Pressure Options with the Nelson Advantage

- Exceptional Uniformity for Maximum Yield & Grade

- American Made with Precision Engineering

- Reliable and Built to Last for Year After Year

- Readily Available Parts & Accessible Service Technicians

- A Manufacturing History of More Than a Century

Efficient / Effective / Economic

Nelson Irrigation dates back to 1911, but a lot has changed in the field since, and we're proud to provide clients with all the most advanced systems today. Our founding mission, however, has remained the same: Save water, save energy, and save labor while doing a better job of irrigating so crops can thrive.

Over the years, we've always prioritized this efficiency, and the inherent nature of the center pivot–a mechanized move system–had made it a labor-saving device. A revolutionary product, it decreases the length of pipe and the number of sprinklers needed to get the job done right, especially when compared to a solid set system.

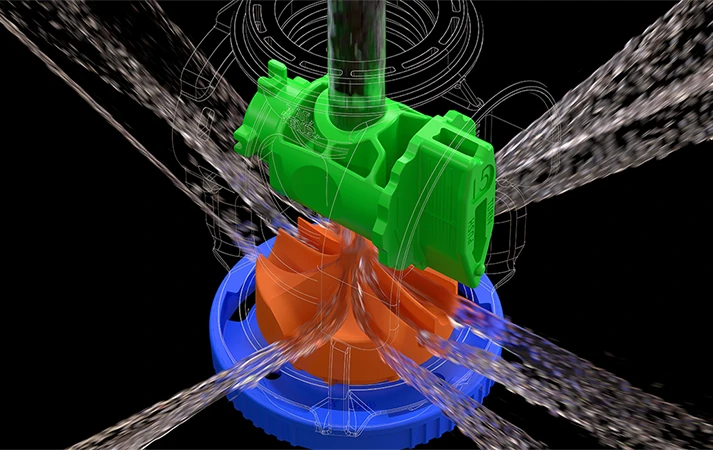

Since the 70s, Nelson Irrigation has been devising ways to bring high-performing, low-pressure products to the pivot market. Whereas operating pressures of 50 psi were once the standard, our innovations have yielded systems with just 6-10 psi. This massive reduction has served to improve pumping costs over the years. Moreover, our highly engineered products–e.g., the Rotator sprinkler with multi-trajectory streams–provide a large wetted diameter that gets more water into the ground while eliminating runoff and waste. When you match the right Nelson products to your specific soil and crop needs, you can ensure maximum efficiency and effectiveness for minimum expense. Take our valves, for example. As hydraulically operated, sleeve-type valves, these custom devices are designed to perform smoothly while providing extremely accurate pressure control and high-flow capacity.

Sprinkler Technology

Different crops, climates, soils, and farming practices demand different kinds of sprinklers. At Nelson Irrigation, we recognize that every client has unique needs, which is why we've devised a family of products with precision engineering to provide a multitude of functions. Put another way, modularity is the cornerstone of every Nelson system.

Our original 3000 Series centered around the 3TN nozzle. With the introduction of the 3NV nozzle, the 3030 Series does even more. To ensure every advancement we make to our sprinklers will actually benefit farmers, we work hand-in-hand with grower-cooperators in the Columbia Basin. They provide real-world input regarding irrigation needs, and we turn around and incorporate their requests for better functionality into our new designs.

Testimonials

At Nelson Irrigation, we're always working to solve your problems before they crop up. As irrigation solution experts, we've spent more than a century innovating, testing, and manufacturing high-quality products, but you don't have to take our word for it. See what past clients have to say about our irrigation systems by checking out the testimonials below.

One of the products from Nelson Irrigation I've been very pleased with is the R3000 system of rotator nozzles. The diameter of the wet surface is much bigger and really reduces the amount of run-off I have, especially on tighter soil.

Dave Collins

Collins Agronomics

With the dependability of the pivots and of the sprinklers, you couldn't ask for a better situation… Nelson and Valmont work together when they're making packages. I pick my partners, and those are the two I pick for my irrigation system.

Mike Hawman

Hawman Farms Inc.

Nelson's customer service is outstanding. They stand behind their products... They've done some replacements for things out here that I really thought went above and beyond what was expected, but it certainly has built the relationship with our customers.

Pat Shannahan

Holzfaster's Equipment, Inc.

PivotMapper

Nelson Irrigation Corporation is proud to offer PivotMapper – the first map-based information solution designed to connect you with important and quickly evolving information used every day to sell, operate and service center pivot irrigation systems. PivotMapper is based on the idea that it is easier to find information on a digital map than in a filing cabinet. PivotMapper makes it easy to quickly map locations and securely store information about the center pivots you manage. Imagine sharing with your team real time dynamic information, anytime and anywhere – in the dealership, on the road, and in the field.

Celebrating 50 years!

At Nelson Irrigation, we have been perfecting center pivot irrigation systems for half a century.

Innovation is an ongoing process, and we're always looking for ways to enhance our irrigation systems, so you can improve your crop yield year after year. From our Big Gun® series to our sprinklers and regulators, we've got a long list of exceptional products that are always being upgraded so they ensure maximum functionality.

World-Class Manufacturing

From our inception, we have made a conscious effort to maintain one manufacturing facility in our hometown of Walla Walla, Washington. This allows for total quality control, so we can provide the highest-quality systems to our customers. To this day, our products are made in America with integrity and ingenuity, and they're built to last for years to come.

If you hear us mention the “Nelson Way,” we're talking about our commitment to delivering state-of-the-art water application solutions. Every single member of our team takes our craft seriously, and we're proud to hire brilliant people who would rather invent better devices than merely manufacture good ones that already exist.

Center Pivot Webinars

Overview of Nelson Center Pivot Sprinklers: Best Practices and What's New

Preseason Water Application Startup Checks for Center Pivots

Pivot Wheel Track Mitigation & Maintenance

LEPA-LESA-LENA Irrigation for Center Pivots

End of Iron

Irrigation and Soils

Center Pivot Irrigation Latest Related Blog Posts

Choosing the right water application package

Saturday, July 25, 2020

Understanding the factors that affect pivot water application performance is important when considering today's technology options.

Give your system a proper check-up

Saturday, July 25, 2020

In today's increasingly competitive global market, high production efficiency is essential for producers to grow their economic return.

Profitability In Irrigation

Thursday, August 1, 2019

Successful growers know the importance of irrigation uniformity in maximizing these inputs for yield and grade. At the same time, rising energy costs are a continuing challenge.

GeoCropical® Solutions

Our devices have endless customization options, which means they can be tailored to your particular GeoCropical® profile with ease. We have a full line of sprinklers that are fine-tuned for specific climates, soils, terrains, crop rotations, and water qualities.

The following crops thrive with mechanized irrigation: corn, potatoes, sugarbeets, sugarcane, soybeans, hay, forage, and more. If you happen to grow something else, though, give us a call to discuss your unique needs. At Nelson Irrigation, we're always up for a new challenge!

Center Pivots in the Media

The YouTube channel Smart Every Day has recently published a great video on center pivots. In depth look at how a center pivot is assembled and the basic concept about irrigating in a circle. See it here

A Brief History of Center Pivots

In center pivot irrigation, the equipment rotates around a pivot, thereby watering a circular area. Sometimes called “water-wheel” or “circle irrigation,” the center pivot method is renowned for its ability to use water efficiently and ultimately maximize a farm's overall yield. This approach is especially effective on large land fields. While center pivots were initially water-powered, today's systems are typically propelled by electric motors. The advancement of these systems is an interesting one; read on to learn more!

Invented in 1940 by Frank Zybach, a farmer in Colorado, center pivot irrigation was initially finicky. Zybach honed the system over the years and by 1952, he was ready to go into business. He partnered with A.E. Trowbridge, who put up $25,000 and received 49% of the patent rights in return. The two men opened a shop in Nebraska and sold 19 systems during their first year in business.

Initially, few farmers understood the benefits of using center pivots to irrigate their crops, but Zybach was not deterred. In fact, during the early years, he didn't even try to sell the system; instead, he focused on improving the overall design so eventually he couldn't be ignored.

In 1954, Zybach licensed his patent to Robert Daugherty of Valley Manufacturing. Daugherty's engineers spent another decade refining the center pivot irrigation system and ultimately converted it from a hydraulic power system to an electric one. Valley Manufacturing evolved to become Valmont Industries, with Valley remaining a subsidiary that continues selling center pivot irrigation equipment to this day.

The center pivot system has undergone a lot of innovation over the years. Today, it's comprised of several segments of pipe–typically aluminum or galvanized steel–with sprinklers positioned along them. The sprinklers are supported by trusses, which are mounted on wheeled towers. The machine as a whole moves in a circular pattern and is fed with water from the pivot point at the center.

The center pivot system was designed for relatively flat terrain. One major advantage of its configuration, however, is that it can function in undulating country, or fields that essentially roll up and down in a wave-like pattern. As such, center pivot irrigation has made it possible to irrigate areas that are unsuitable for other systems, including those in the Middle East and the Sahara.

Download our Center Pivot product Guide

Check out our handy pocket guide for quick access to product performance and center pivot tips and tricks. Pages 16-19 cover important calculations such as determining depth of water applied, average application rate, required system flow and more!